Posted on August 8th, 2022 by Nathan Lioret

In the previous article, we presented to you quite briefly how plastic materials are made, which constitute the bulk of the waste that we will process in Nepal. If the terms polymer, thermoplastics, thermosets, injection, extrusion, rotational molding… are not familiar to you, I invite you to read our previous article [Plastic in all its forms].

Before starting to recycle plastics, which will be the subject of the next article, we must sort them according to their type because each type of plastic has specific properties which generally do not allow several types of plastic to be mixed in the same recycling process. We can already think of the importance of distinguishing thermoplastics and thermosets : one can be remelted indefinitely and is thus very suitable for recycling, while the other is fixed forever after its creation, which makes it very difficult to recycle. We will also see that it is very important to clearly distinguish the 7 categories of thermoplastics, some more than others, especially due to different melting temperatures from one category to another. We are getting to the heart of the matter.

Thermoplastic or thermoset ?

A first sorting must be carried out between these two extremely different types of plastics that can never be mixed within the same recycling process. Fortunately, it’s easy to tell them apart, using one of the following two methods.

The first, the most logical, is to heat the plastic to see how it reacts : thermoplastics melt (transition from solid to liquid) while thermosets burn, they blacken without changing of state.

The second method is to scratch the surface of the plastic. When the surface of a thermoset is scratched, particles appear, they stay on the finger when we pass it over the scratch. It is not the case for thermoplastics. [1]

PET, PE, PP, PS….

Now that we have separated thermoplastics from thermosets, we will sort thermoplastics according to their type. We will not be interested in the sorting of thermosets because it is very little developed. Indeed, it is impossible to recycle them and they generally end up incinerated or put in landfills, so there is no need to sort them…

Sorting thermoplastics is a very complex task that can be approached from different angles, we will see the main existing methods, their advantages and disadvantages and finally which ones will be used for our project.

Manual sorting

The method which requires the least technology is manual sorting, “by hand”, carried out by a human who will recognize, according to its color, its texture, its shape, its added elements (labels, recycling symbol, etc.), what kind of plastic it is. This work can be greatly facilitated, especially in Europe, by the appearance of acronyms designating what type of plastic it is. This method is essentially based on the experience of the person doing the sorting, it can be very quick if several people get involved, but it sometimes happens that two different plastic products have the same appearance and the same texture. Errors are therefore quite frequent with this type of sorting.

To see from what plastics the most common objects are generally made of, I invite you to go back to our previous article [Plastic in all its forms] where the classic uses of each type of plastic are detailed in the section “All the same plastics ?”.

The manual sorting method, which is inexpensive and energy efficient, is the method that we will use the most in the context of the Tri-Haut pour l’Everest project.

Sorting by flotation

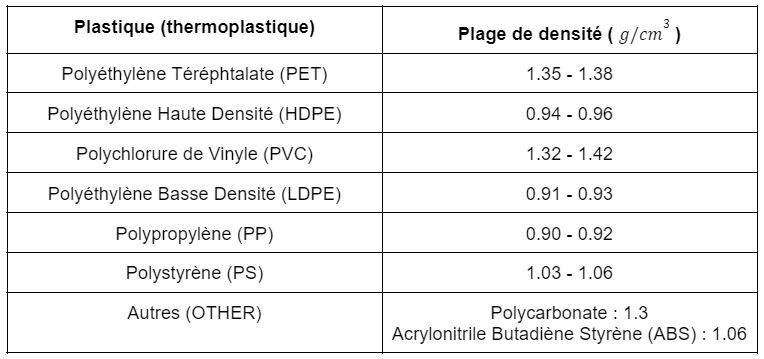

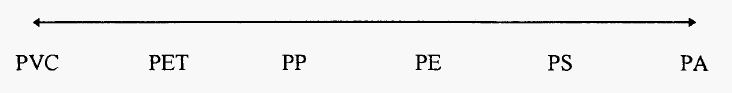

A second widely used method is the sorting by flotation. It turns out that the density of plastics differs from one type of plastic to another. The idea of the sorting by flotation method is to exploit this property to, using successive receptables filled with different liquids, separate the different types of plastic. Indeed, the heaviest plastics will sink while the lightest will float, they can then be easily separated.

For this method to be effective, the difference in density between the materials to be separated must be at least 0.2 g/cm3, particularly to be able to neglect the effect of additives on the density. We can therefore see that it will be difficult to precisely separate PE from PP and PS, for example. However, this method is widely used to separate PET from other plastics (except PVC), simply with water. Other separations, more or less precise, can be carried out using other liquids but we will not dwell on them further.

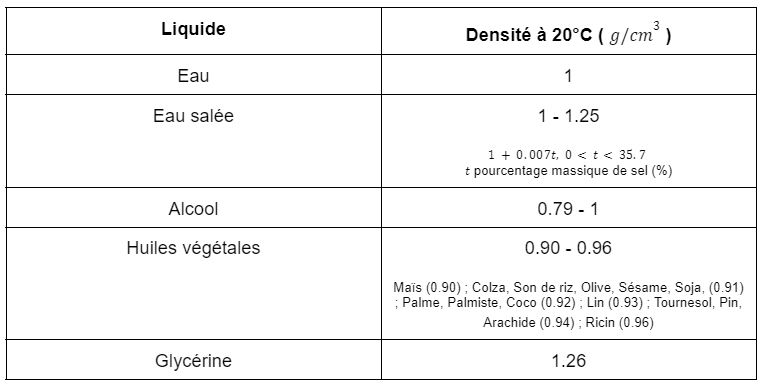

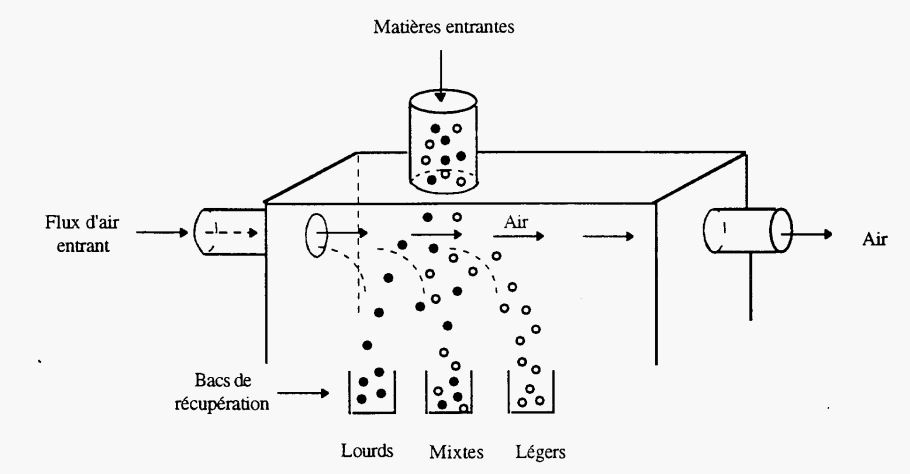

Densimetric sorting

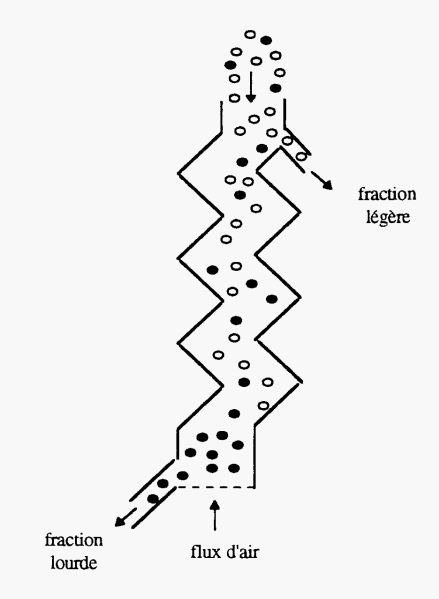

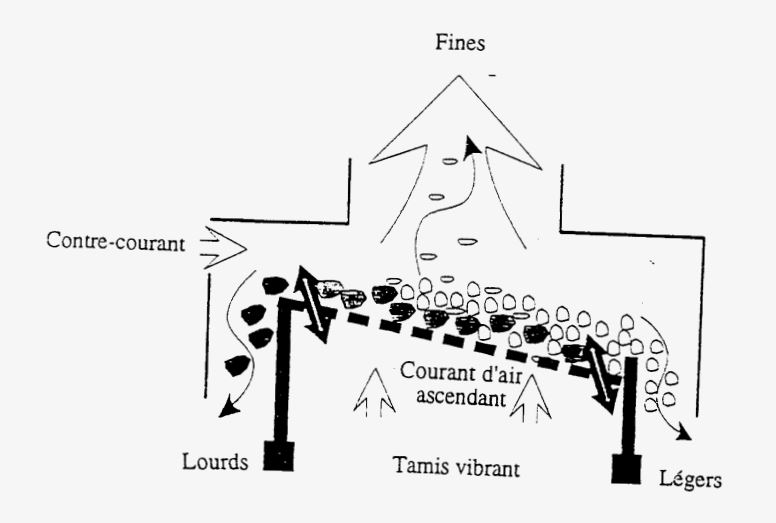

There are other densimetric sorting methods, which are based on the mechanical behavior of a solid in a fluid (liquid, gaseous or supercritical) according to its shape, its density and its surface of contact with the fluid. The shredded plastic is sent in a flow (horizontal, ascending, centrifugal…) in order to be sorted. Some examples of processes using this method are given below :

Air Knife (top left), Zig Zag (right), Cyclone (bottom left) and Fluid Bed Density Table (bottom) methods [2]

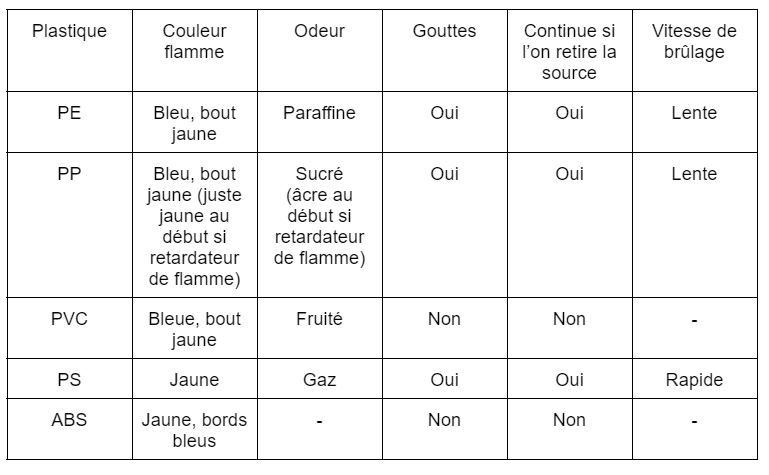

Burning method

Another fairly simple method to implement is the method of sorting by burning. It simply consists in burning a piece of plastic to be sorted in order to determine its composition according to the properties of the flame (color, volume, appearance). This method presents risks since certain types of plastic release toxic fumes when burned (PET, PVC and PS in particular). In addition to this risk, this method is very difficult to industrialize and less effective than other methods that are easier to implement on an industrial scale, so it is not used in the industry. However, it can be used occasionally in sorting situations with low-tech machines, especially to clear up doubts when sorting plastics manually. It is in this second situation that we find ourselves with the Tri-Haut project.

Optical sorting

Let us now see the methods of optical sorting, they can be distinguished into two categories : optical sorting upstream and optical sorting downstream.

The first type of optical sorting method consists in observing the shape, size and color of incoming waste, not yet shredded, to try to determine its type, just as a human would do. These technologies have developed in recent years with the rise of artificial intelligence.

The second is carried out downstream, generally by Infrared spectroscopy (detection of the vibrations of certain chemical bonds at characteristic frequencies) even if other methods exist. In particular infrared pyrolysis which consists in analyzing by infrared spectroscopy not the solid matter directly but the gases emitted during the pyrolysis (combustion without oxygen) of this plastic material using a laser. But also Raman spectroscopy and in the visible (same principle as in Infrared but for different chemical bonds), X-ray fluorescence (detection of atoms that can fluoresce), ultrasonic analysis (measurement of the attenuation of ultrasonic over a given frequency range)… Each type of plastic has different responses to each of these solicitations. However, it is not always so easy to differentiate them, once again because of the different additives that are very often found in plastics and which affect the properties of the material and therefore its response to optical (but also mechanical) solicitations. , electric, etc.). [2]

Electrostatic sorting

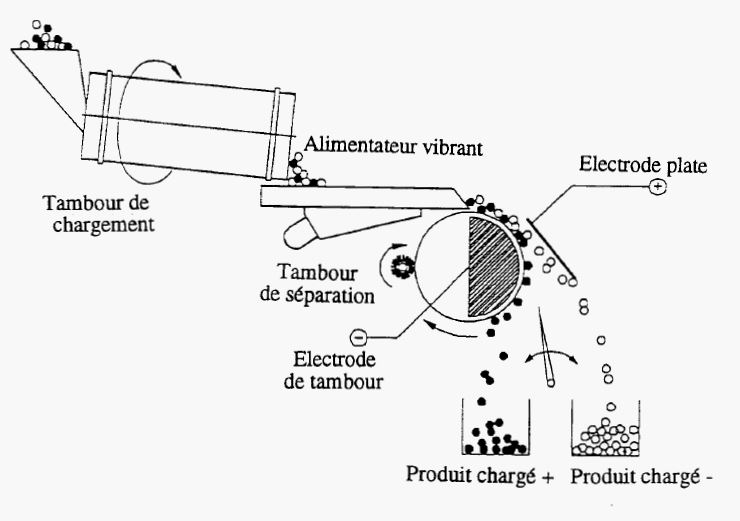

Finally, after the methods of manual sorting, densimetric sorting (flotation, air or water flow, etc.) and optical sorting (burning, upstream, downstream), sorting methods using the specific electrical properties of each type of plastic exist. To exploit these properties, it is necessary to charge the plastic particles, several ways of doing this exist : by triboelectricity (intensive friction of different particles between them, in the manner of a balloon with our hairs), by conductive induction (setting a charged surface with the uncharged particles of the plastic) or by ion bombardment (the reverse of conductive induction : the plastic is charged but the fixed surface is not). Then, if the size of the plastic elements is small enough for the electrostatic forces to be greater than the forces of gravity and inertia, if they are dry and of homogeneous granulometry, then the plastics can be sorted by this method. [2]

Sorting by selective dissolution

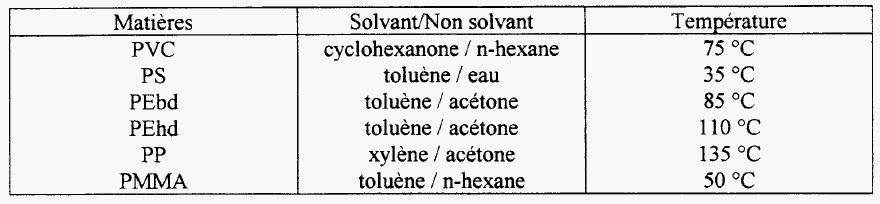

The last method presented here is the so-called selective dissolution sorting method. It consists in placing the mixture of plastic that one seeks to sort in different solvents at specific temperatures, in which certain types of plastic will dissolve and not others, to highlight the types of plastic present in the mixture. . By successively applying this method until the mixture is completely dissolved, it determined which plastics are present.

We can also mention magnetic sorting, which does not directly allow plastics to be sorted among themselves, but which nevertheless allows metal elements to be removed from the waste. It is a method that acts upstream of the actual sorting and is widely used industrially.

Now that we have seen the main types of plastic and the different methods used to separate them, we can now look how to recycle it, and how to apply it on a small scale as in the case of the Tri-Haut project.

Sources

[2] RECORD, Etat de l’art concernant les méthodes de tri des matières plastiques, 1998, 223 p, n°96-0901/1A.

[3] https://www.boedeker.com/Technical-Resources/Technical-Library/Plastic-Identification