The incinerator in 2 minutes

Posted on 27/12/2020 by Valentin Girard

So what we are going to do is that we will first explain to you how an industrial incinerator works, and then why we will have to adapt ours and how. Okay with you ? Here we go.

A short video is better than a long speech, right ? We found a super well done one for 1 minute 15 (in French) :

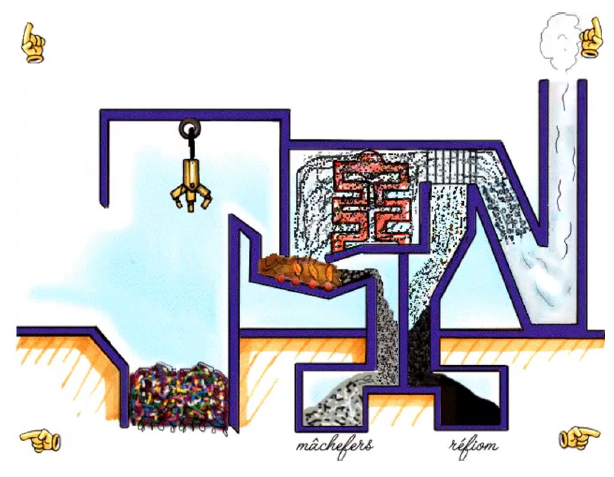

For those who were lazy, here is a little recap in pictures

- The waste is pre-sorted. Excessive waste and large metal waste are discarded.

- The rest goes into the storage pit. A clamp supplies the combustion chamber.

- The combustion chamber has previously been heated with town gas, and is always maintained above 850°C for complete and clean combustion of the waste.

- What has not burned is called clinker. It is composed of ashes and metals. They are stored, and can be reused to stabilize land for example.

- The fumes are very hot. This heat is often used to make electricity with advanced steam engines, and/or to heat water for the city’s heating network.

- The fumes are filtered with lime and coke to pollute the atmosphere as little as possible. What is recovered is called the refiom. This powder is very toxic to the environment. It must be treated with great care.

- The rest of the fumes are evacuated by high cooling chimneys.

- If the combustion chamber must be stopped, it must be done gradually so as not to produce too much smoke and solid waste.

Sounds easy on paper, right ? But hey, you can imagine, we won’t be able to make an industrial incinerator at 4000m. This would be well above our budget, but also unsuitable for the terrain, and the amount of waste to be incinerated. We have another problem : the environmental conditions. This puts a spoke in our wheel for 3 main reasons :

- Firstly, there is less oxygen at this altitude. And lack of luck, it is very important for the combustion. It will be necessary to bring more air inside the combustion chamber to have enough oxygen.

- But that poses a second problem : it’s freezing in the mountains. And you remember, we said above that the combustion chamber must be at least 850°C to ensure good combustion, which does not pollute too much. Not easy if you bring in a lot of cold air, and the walls of the incinerator are cold.

- Finally, in Nepal, and in addition at 4000m altitude, it is impossible to imagine someone picking up bottom ash and refiom, and treating them in good conditions. A solution will have to be found.

So what are we going to do ? Or at least what would we like to do ? Well, a bit like an industrial incinerator, but integrating low-tech technologies, and smaller. We have a little less than a year to design an incinerator which :

- Burns all non-metallic waste that would end up in the rivers else.

- Limit air pollution.

- Recycles waste by producing electricity and/or hot water.

- Is the easiest to manage for local people.

- Can be installed at altitude, and which adapts to the climatic conditions of Khumbu.

- Produce as little residue as possible (bottom ash and refiom).

To help us integrate all this, we benefit from the work carried out by the Falchen Kangri association. It is an association of INSA Lyon which went to install an incinerator in the Himalayas at an altitude of 5000m.

It is therefore a great challenge that is offered to us today.

But we accept this challenge with open arms, and we are sure that with our motivation and your support, we can do it !