The machines

The shredder

The shredder transforms plastic waste into small shavings. This is an essential step for the use of the other machines.

We had the shredder delivered to Kathmandu in 2021, where we assembled and studied it in order to produce a precise technical document for the people who will be looking after it in the valley.

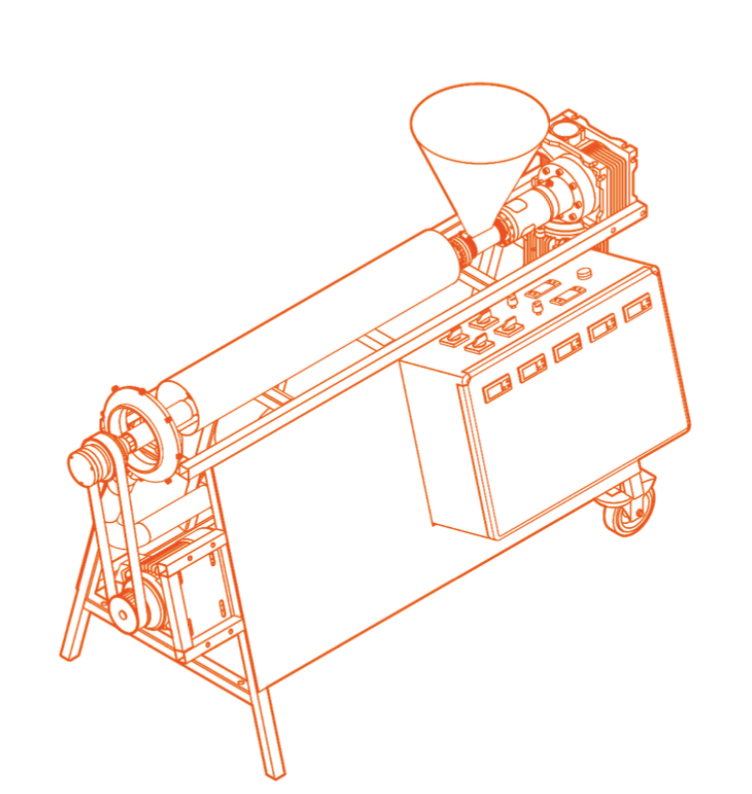

The injection machine

Plastic shavings are heated and injected into a mold. It’s a relatively quick process, ideally suited to the production of small objects.

We bought the injector from “l’atelier des recycleurs fous” and it was Johe Bruneau who designed the object, the yak, and made the mold in an aluminum foundry in France.

The money generated by the sale of items will pay for 2 employees to run the center.

La Sheetpress

The sheetpress is used to manufacture plastic sheets measuring 1 m on each side, which can then be cut, assembled or folded to create objects of all kinds, such as chairs, shelves, tables, tiles, cutting boards… A whole host of objects useful to the local population.

We built it in Kathmandu, where it will remain and be used by Madindra Aryal to make furniture.

Une future machine: la centrifugeuse

The centrifuge (Polyfloss type) transforms plastic waste into polyester (fibers), a thermally insulating material that would be very practical in this region where temperatures can drop very low and no insulation system is in place.

Another big advantage of the centrifuge is that it works with PET plastic, a type of plastic that doesn’t work in other machines (except shredders) (see Plastic in all its forms).

To find out more about low-tech plastic recycling machines, please refer to our article Low-tech plastic recycling.