Posted on August 15th, 2022 by Nathan Lioret

In this third and last article on the manufacturing and recycling of plastic, we will see different low-tech methods of plastic valorization. We will see the methods we came across during our researches for the Tri-Haut pour l’Everest project, without claiming to give an exhaustive list of all the existing methods neither.

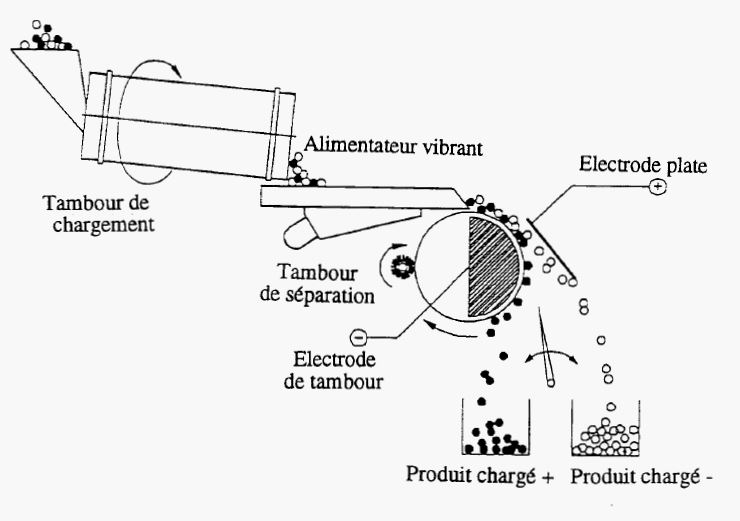

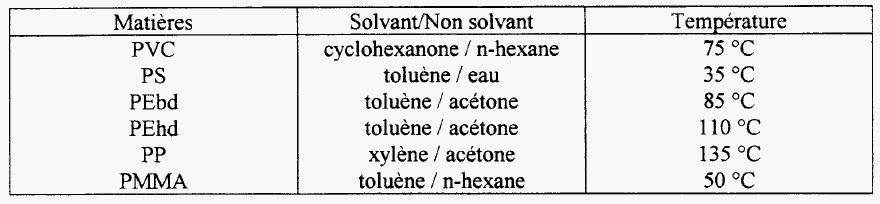

Let’s first look at the preliminary steps of most recycling methods : sorting, shredding and washing. Regarding sorting, we studied it extensively in the previous article, [Sorting plastic], I invite you to read it if you haven’t do it yet.

Shredding

When shaping plastic objects, the raw material is generally made of small homogeneous plastic flakes that are melted and shaped using different processes (see our previous article [Plastic in all its forms]. Many recycling processes, low-tech or not, use the same shaping principles, but to do this, the waste must be transformed again into small homogeneous plastic elements : the small size of the elements is ensured by the shredding step, performed by a shredder. Check out this rather satisfying video of a shredder swallowing a plastic bottle and spitting it up into small flakes :

There are many shredder technologies, at very different scales because this step is essential for any recycling center, whether it is a small low-tech center like the one we will build with the Tri-Haut, or a large industrial center.

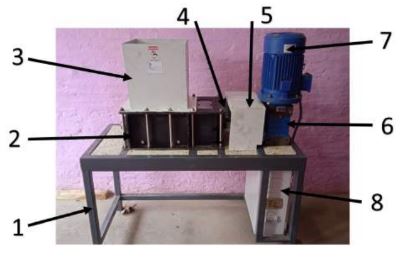

Among all these technologies, we chose the one proposed by the Precious Plastic community, a global community for low-tech plastic processing that greatly inspired us as we will see in a next part. Its principle is quite simple, it involves rotating two sets of curved blades in opposite directions to vacuum while cutting the waste into small pieces.

1. Frame Table 2. Shredder box 3. Hopper

4. Transmission 5. Transmission protection

6. Gearbox 7. Motor 8. Electric panel

There are centers only specialized in crushing the plastic wastes, which then sell the small pieces obtained to manufacturers so that they can make new objects from them. It is common for PET plastics (plastic bottles), which are the most recycled, because their purchase is often more expensive new than recycled, which is not necessarily the case for other types of plastics.

Washing

As we saw in the previous section, most recycling processes require raw materials (made from plastic waste) made of small pieces of homogeneous plastics. Washing, combined with sorting, ensures the homogeneity of the plastic. It consists in removing the added elements from the objects (labels, aluminum film, etc.) and cleaning it of impurities (soil, dust, food remains, etc.).

Once again, different technologies exist at all scales because it is a step almost as essential as shredding. It is usually done after the shredding so that all surfaces can be cleaned up (for example, the inside of a closed bottle is inaccessible before shredding).

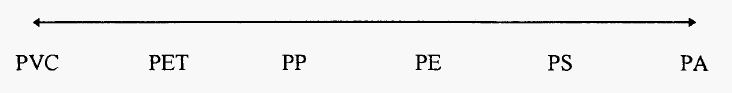

The first step is to clean the plastic flakes, usually with water, either in the style of a washing machine with a rotating drum, or by stirring a tub of water in which the flakes float. It is this second option that Plastic Odyssey, an organization fighting against plastic pollution, which we will describe more precisely later, have chosen with their washing machine. This method works well with lightweight plastics (PP, PE, PS) which float on the surface while impurities sink. It works less well with PET and PVC which are also heavier than water.

A second centrifugation step separates the last impurities as well as the humidity due to the first step. For this, a centrifuge is used, both on a low-tech scale and on an industrial scale. The vertical centrifuge presented by Plastic Odyssey simply consists in rapidly rotating a cylinder surrounded by a hopper large enough to allow impurities and water to pass through but still smaller than the plastic flakes. Thus, pure, dry and dirt-free plastic is obtained, the ideal raw material for the following machines.

Precious Plastic

We already talked about Precious Plastic machines in the shredding part without explaining what this community really was.

Precious Plastic is a low-tech plastic recycling project, meaning on an artisanal scale. It was launched in 2012 by Dave Hakkens and aims to democratize plastic recycling by allowing anyoneto set up his own miniature recycling plant. To do this, plans for inexpensive machines as well as tutorials on how to assemble them and how to operate them, or how to manage different types of recycling workshops, are available in open source on their website (https://preciousplastic .com/index.html). You can also buy the machines directly from people who make them, which is what we did for our project. Finally, the idea of Precious Plastic is to bring people together in local communities for the recycling of plastic.

Among the machines presented by Precious Plastic, we obviously find the shredder and the washing machine that we previously saw, but also four machines intended for shaping plastic :

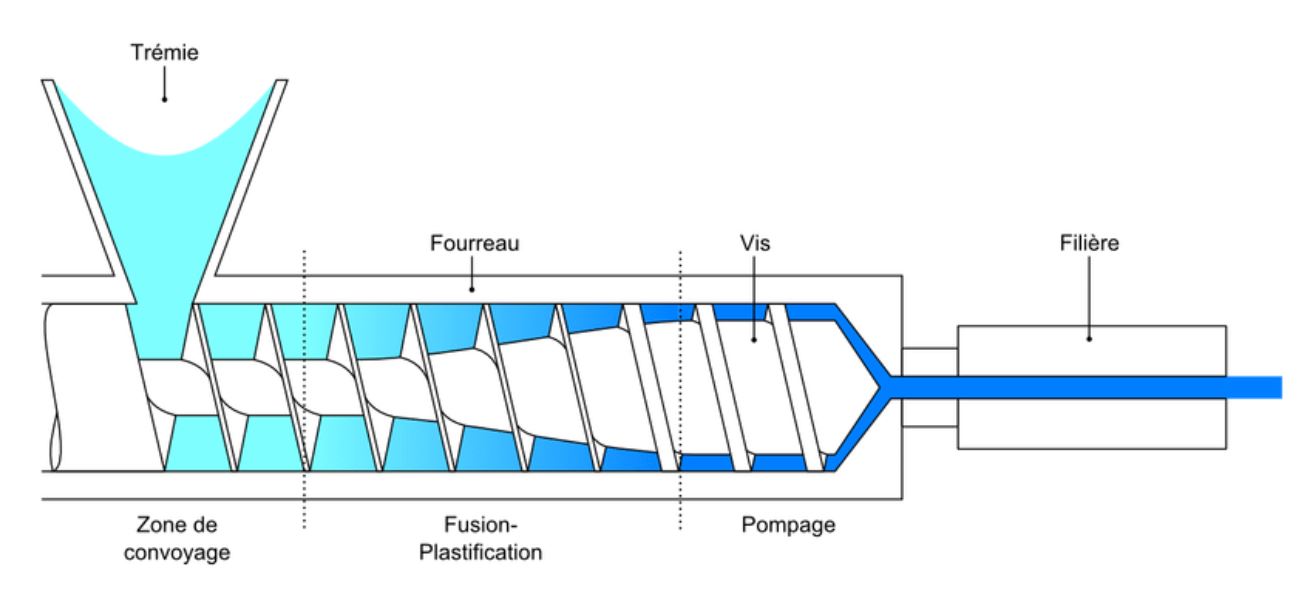

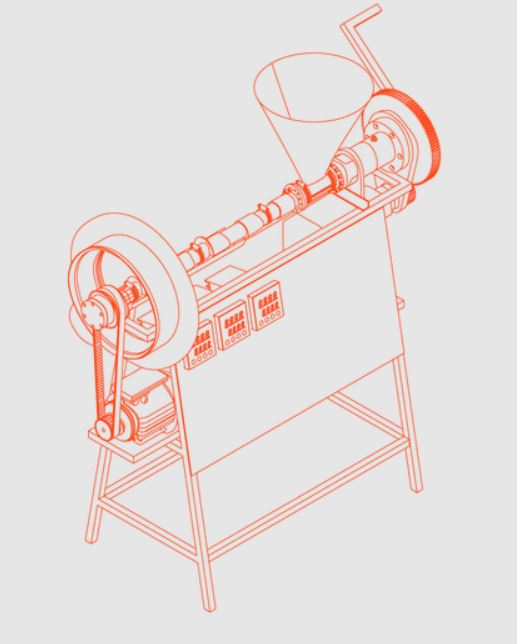

- The extruder transforms the shredded plastic into a wire in the shape of the mold placed at the outlet. The principle is quite simple : an endless screw heats and conveys the shredded plastic to the mold which, under the pressure exerted by the continuous supply of material, comes to give its shape to the plastic, which cools once in the open air , to freeze its shape. Starting from this wire, or from profiles of different shapes, it can be kept as it is or rolled up on itself like wicker. You can also place another mold, a closed one, at the exit of the extruder to create beams, which can then be twisted and assembled (see the following video).

- The plastic sheetpress makes it possible to manufacture sheets from palstics, as its name suggests. It is simply a matter of compressing plastic between two plates, heating it so that it can stick together. These plates can then be cut, twisted by heating them locally using moulds, and assembled to create objects, in particular furniture or containers.

- Precious Plastic’s injection molding machine is a miniature version of those used in industry, just like the extruder. It makes it possible to create small objects by injecting heated plastic into a mould, again using an endless screw. The plastic will then take the shape of the mold and give the desired object once cooled.

- The compression machine looks a bit like the sheetpress. It involves filling a mold made up of two parts (bottom and top) with plastic flakes and putting the whole thing into an oven between two plates which will compress the whole thing so that the plastic takes the shape of the mold once cooled.

The main problem with Precious Plastic machines is their inability to process PET plastic, which is very difficult due to a very precise melting temperature range compared to other plastics, and a tendency to crumble when cooled down. Only the injection molding machine can possibly be used with PET, for very small objects. Precious Plastic machines work best with PP and PE.

By combining the use of these machines, one can create an infinity of plastic objects : table, spinning top, key ring, chair, basket, crates, bricks, “works”…

Plastic Odyssey

Plastic Odyssey is an organization from Marseille which fights against plastic pollution at sea. To do this, it seeks to act upstream, that is to say directly with the populations who produce the plastic wastes, by encouraging them and helping them build their own low-tech recycling machines. They also work with populations to find solutions to reduce their plastic consumption, particularly regarding the single-use plastics.

You can find on their website (https://plasticodyssey.org/), in the same way as for Precious Plastic, a whole set of low-tech machines in open source. Among them, we find again a shredder and a washing machine, but also an extruder, an hydraulic press, a plate oven, a compactor and a pyrolysis.

- Plastic Odyssey’s extruder works roughly in the same way as Precious Plastic’s one although it is much more powerful (about 5 kW for Precious Plastic’s pro extruder vs just under 50 kW for Plastic Odyssey’s) , but therefore also more expensive, heavier, more voluminous… A barrel is also offered by Plastic Odyssey, it is a support for the molds making it possible to produce profiles of various sizes and sections, it makes it possible to optimize the use of these molds by avoiding having to stop the extruder each time the mold is changed (but simply to turn the barrel), unlike the Precious Plastic extruder.

- Plastic Odyssey’s plate oven creates plates from plastic flakes. It is simply a matter of heating the plastic in a mold in the form of a plate. But unlike the Precious Plastic sheetpress, here the plates are not compressed. If you want to obtain smooth and compact plates, you have to place them still hot in the hydraulic press that we will see just after. With Plastic Odyssey’s technology, it therefore takes two machines to do what Precious Plastic does with a single machine. But the hydraulic press can be used differently too, as we will see shortly.

- The hydraulic press already makes it possible to greatly improve the quality of the plates produced by the plate oven, as we saw ust before. But its scope is much wider than simply creating flat plates. The major interest of the hydraulic press appears when you place a mold (in two parts : fixed and mobile) between the two plates and you put material between these two parts of the mold. Either material coming out of the extruder or a plate coming out of the plate oven, in all cases it must still be hot and malleable. By then exerting a strong uniform pressure on the mould, thanks to hydraulic cylinders, the material is forced to be distributed throughout the mold cavity. One thus obtains, once cooled, very diverse objects according to the molds chosen. It is similar to the compression machine from Precious Plastic, but without heating.

- The compactor does not really recycle the plastic, it simply makes it possible to compact the waste into compact bales so that they take far less space if we want to transport them or simply store them. This considerably reduces the volume occupied by the waste, but it then becomes more difficult to separate them in order to sort them because they are tangled in the bale.

- We will talk more about the pyrolysis in a future section, and even more in our dedicated article [The pryolysis].

Polyfloss Factory

Polyfloss Factory is a small British company, initially created by London students, which created a machine for transforming PP and PET plastics into insulating wool for buildings and clothing (down jackets, sleeping back, etc.).

This machine is of great interest for low-tech plastic recycling. It is the only machine to easily and efficiently recycle PET plastics, which are very difficult to process with Precious Plastic and Plastic Odyssey machines due to their very precise melting temperature and tendency to crumble on cooling. However, it is optimized for the treatment of PP. In addition, it makes it possible to process fairly large quantities of plastic (10 kg/hour) and this continuously, we only need to feed it with plastic. It consumes relatively little electricity (600 W, compared to 5 kW for a Precious Plastic extruder for example). Finally, it is easy to use and maintain.

Regarding its many advantages, it is obvious that such a machine will be present in our sorting center at the bottom of Mount Everest !

Art

It is not really a low-tech recycling method, but it’s interesting to see what some people manage to create as works of art from simple plastic waste collected in landfills like we find so much in Nepal, and in many other countries of the world sadly.

The best example for this is the Sagarmatha Next project, which is located in the same valley as our project, a little below. Take a look on there website if you’re interested : https://www.sagarmathanext.com/.

The pyrolysis

With the pyrolysis, we are entering methods that are a little further from actual recycling, but which still allow a certain valorization of the wastes. It makes it possible to treat the waste that are difficult to recycle (too dirty, too mixed, already recycled several times, etc.).

We saw in the first article of this series of three articles on plastic, [Plastic in all its forms], that plastics are in fact an assembly of hydrocarbon molecules placed end to end to form a long chain, namely polymers. The idea of the pyrolysis is to perform the reverse process : by heating the plastic in the absence of oxygen, to over 450°C, the plastic evaporates and its bonds break : part condenses into fuel oil, another part remains in gaseous form, and a last small part forms wax, a solid substance which we do not yet know what to do with.

It is common to carry out the pyrolysis process (heating and condensation) several times in a row using several condensers (3 for our prototype) in order to improve the quality of the fuel oil. The gas produced can also be used to heat the combustion chambers. In our case, as electricity should not be a problem due to the upcoming construction of an hydroelectric power station in the valley, we are trying to recover this gas to allow the inhabitants to heat themselves in particular. Our research continues on this point, and on the wax as well.

The advantage of the pyrolysis is that it requires less pre-treatment phase than for recycling machines : if the shredding upstream is highly recommended, washing is not essential, although it allows to improve the results obtained, as shown by our experiments on the prototype. This is a very efficient process for PP and PE plastics but does not work very well with other plastics like PET…

As this technology is not yet fully mature, due to difficult industrialization and low oil prices, we are doing a lot of research and experiments on pyrolysis.

If you want to know more, last year we wrote an article dedicated to this process on our website, [The pryolysis]. We will update it as we progress.

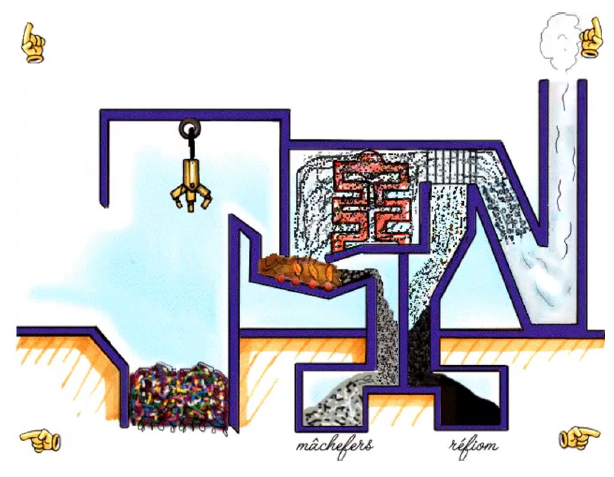

The incinerator

Incineration is not a recycling method as such, either, but it can make it possible to recover energy from plastic wastes by recovering the heat produced, either directly by injecting the heat into a heat network, or by transforming it into electricity.

We won’t dwell on this widespread technology because we already did it in a previous article, [The Incinerator], when we were still planning to install an incinerator in the valley.